Chemical Lubricant Blending and Packaging Services

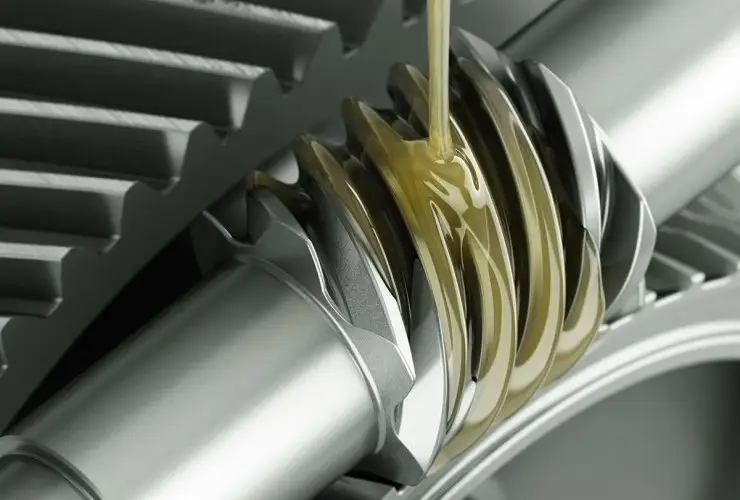

As high-performance machinery becomes more advanced, their requirements become more specific. This means lubricant formulation must keep up with the changes, and SolvChem® Custom Packaging Division is at the forefront of the industry.

We’re your full-service lubricant blending partner, providing a customized approach to the process of chemical blending and lubricant packaging that ensures you have the right products for your needs.

As machinery becomes more sophisticated, the chemical lubricants they use must be able to match it. We’re committed to making sure our blending process is up to the challenge.

Base Oils and Additives for Custom Lubricant Blends

Our lubricant oil blending processes begin with selecting the proper base oils for the desired results. Whether derived from mineral sources, plant-based or synthetic, a base oil offers different properties depending on its quality. The most crucial of these are its viscosity, its thermal stability and its resistance to oxidation. The choice of base oils comes down to how well each one performs in the categories that are most important for the given application. SolvChem® Custom Packaging Division offers the flexibility to work with synthetic, mineral, and eco-friendly base oil options.

Once the base oil is selected, the next step is to determine which lubricant additive formulations need to be blended with it to achieve the proper balance of properties and characteristics. Some common examples of additives include:

- Corrosion inhibitors

- Viscosity enhancers

- Detergents

- Anti-wear chemicals

The proportions of each additive and the base oil have to be precise in order to achieve the desired effects in the finished product. This process is absolutely critical for developing the high-performance industrial lubricants required by today’s advanced machines.

Quality Assurance in Lubricant Blending

Given the high expectations put on lubricant oil products today, quality assurance is a high priority. Any lubricant blending issues that are not addressed during the process can lead to serious problems with performance in machinery. This is why SolvChem® takes great care to adhere to the highest standards of quality when blending our specialty lubricant solutions. We’re capable of solving any concerns you may have about our products pertaining to chemical regulatory compliance. The level of expertise and experience we have in the field means we’re primed and ready to help you find the right solution for your needs without running afoul of any applicable regulations.

We have perfected strategies for maintaining consistently high quality in automotive lubricants as well as aftermarket automotive chemicals and windshield solution fluids. We want you to have the utmost confidence in what we provide for you, which is why we never take shortcuts, and we’re constantly vigilant about our QA processes. We have the expertise and capabilities needed to support your regulatory requirements and maintain consistency across automotive and aftermarket blends.

Custom and Eco-Friendly Lubricant Solutions

We understand that your requirements are unique, which is why we take a fully customized approach to lubricant blending and formulation. We never try to foist a one-size-fits-all solution on you, instead taking the time and effort necessary to develop the ideal solution for what you need your liquid lubricants to do.

This includes understanding your requirements with regard to sustainability. As markets demand more eco-friendly options, we have answered the call and worked diligently to improve the impact our activities and products have on the environment. We’re here to help you meet your sustainability goals in any way we can with tailored formulations, eco-conscious initiatives, and alignment with your customer sustainability goals.

Partner with SolvChem® CPK

SolvChem® Custom Packaging Division stands at the forefront of the chemical blending industry, setting new standards in how products including lubricant oil are formulated and distributed. Our status as a leading-edge blender and packager means we’re always adapting to the newest technologies and sustainability standards when it comes to total lubricants blending. If you’re ordering in large quantities, we also provide chemical storage and warehousing services. With our location close to Port of Houston, flexible order sizes, storage services, and expertise in hazardous blends, we’re the ideal partner for your needs.

Request a Quote for Lubricant Blending Services

To learn more about everything our lubricant blending capabilities can do for you, reach out and speak with a member of our team today.

High-Quality Custom Chemical Solutions

Contact us for reliable, custom chemical packaging and blending. Our team ensures products are catered to your exact specifications, with on-time delivery, every time.